Empowering Small Business: Big Company AI Accessibly Delivered

We democratize artificial intelligence, making enterprise-grade capabilities accessible and impactful for small to medium size enterprises. Our pilot-first, outcome-driven approach de-risks investment, ensuring sustained, measurable improvements and a shortened path to ROI.

The Landfall Framework is our proven methodology for de-risky your AI investment. Starting with a high-impact pilot to deliver a rapid, measurable ROI. This initial success then becomes the strategic foundation for scaling intelligent solutions across your entire enterprise, ensuring a predictable path from you first win to total operation transformation.

DIAGNOSTIC & PILOT DESIGN - rapid strategic diagnostic to pinpoint the single highest-impact, lowest-complexity AI pilot project that will deliver a clear and immediate business win.

PILOT IMPLEMENTATION - swift execution of the pilot project, focused on rigorously quantifying its value and delivering a confirmed, high-ROI "quick win" to validate the business case.

OPPORTUNITY MAPPING - strategic planning phase where we leverage the insights from the successful pilot to build a comprehensive, multi-wave roadmap for scaling AI across your entire enterprise.

SCALED IMPLEMENTATION - full-scale operational rollout, where we systematically deploy prioritized AI solutions from the roadmap using an agile and continuous learning mindset.

HANDOFF - final knowledge transfer, where we stabilize the new systems and provide comprehensive training to empower your team to confidently own, operate, and iterate on the solutions independently.

Latest News & Blog Posts

Contact Us

Interested in working together? Fill out some info and we will be in touch shortly. We can’t wait to hear from you!

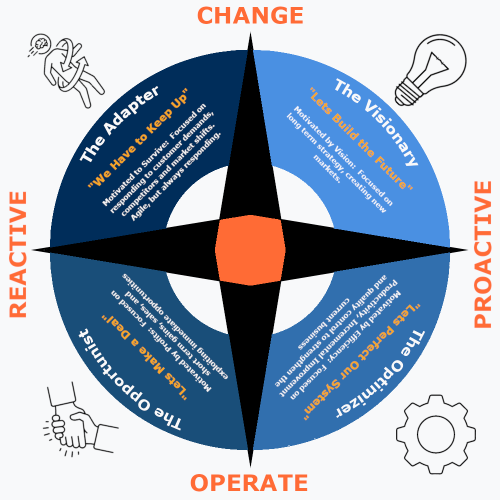

Let's be honest about how traditional maintenance works in most shops. We operate in one of two modes:

1. Reactive ("Run-to-Failure"): This is chaos. A machine breaks, production stops, and everyone scrambles. It’s the most expensive way to run a business, period. You pay for overtime labor, expedited parts, and lost revenue.

2. Preventive (Calendar-Based): This feels more responsible, but it’s incredibly inefficient. You replace a spindle bearing every 2,000 hours because that's what the manual says. The problem? That bearing might have had another 1,000 hours of perfectly good life left in it. You just threw away a good part and paid a technician to do it.

This "just-in-case" approach to maintenance is a drag on your finances. It inflates your COGS with unnecessary parts and labor, ties up cash in your spare parts inventory, and still doesn’t prevent every failure. Why? Because a calendar doesn't know if you were running tough-to-machine alloys last month or if a new operator is pushing the machine harder. It’s a guess. A costly one.