The "Great Compression" is here - It took business 16 years to adopt the personal computer...AI tools will be adopted in less than 3!

The "Great Compression" has arrived.

The pace of disruptive business technology adoption is accelerating exponentially. While the Personal Computer took 16 years to reach 50% business adoption, AI tools are projected to take less than 3 years.

This rapid adoption is fueled by a significant shift in deployment: moving from top-down capital investment (as seen with the PC) to bottoms-up, individual employee adoption (similar to the smartphone and now AI). With employees independently adopting AI tools, organizations can no longer rely solely on robust governance.

To thrive in this new landscape, companies must adopt a default state of continuous adaptation. Organizational Velocity—the ability to learn, test, deploy, and scale new business models swiftly—has become the most crucial competitive advantage. The "Industrial AI" era necessitates fundamental enterprise transformation, and those who fall behind will face rapid decline.

Do you understand your Culture Compass™?

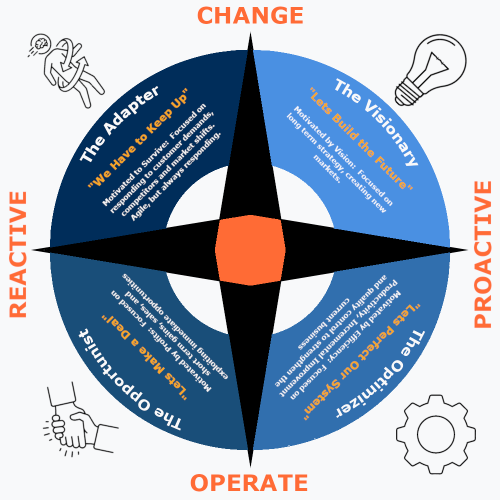

Strategies fail when they force a cultural shift that is never explicitly managed. The compass maps an organization's cultural bias on two axes, "Reactive-to-Proactive" and "Operate-to-Change," to identify four distinct personas: The Opportunist, Optimizer, Adapter, and Visionary. It argues that failure is often caused by the "Quadrant Jump"—the unrealistic assumption that a company can leap directly from one persona (like "Opportunist") to its diagonal opposite ("Visionary").

Your Preventive Maintenance Schedule Is Quietly Killing Your Margin

Let's be honest about how traditional maintenance works in most shops. We operate in one of two modes:

1. Reactive ("Run-to-Failure"): This is chaos. A machine breaks, production stops, and everyone scrambles. It’s the most expensive way to run a business, period. You pay for overtime labor, expedited parts, and lost revenue.

2. Preventive (Calendar-Based): This feels more responsible, but it’s incredibly inefficient. You replace a spindle bearing every 2,000 hours because that's what the manual says. The problem? That bearing might have had another 1,000 hours of perfectly good life left in it. You just threw away a good part and paid a technician to do it.

This "just-in-case" approach to maintenance is a drag on your finances. It inflates your COGS with unnecessary parts and labor, ties up cash in your spare parts inventory, and still doesn’t prevent every failure. Why? Because a calendar doesn't know if you were running tough-to-machine alloys last month or if a new operator is pushing the machine harder. It’s a guess. A costly one.

Stop Wasting Money on Failed AI Pilots: How to De-Risk Your Investment and Actually Drive Value From the Shop Floor Up

I’ve spent my career engaged in manufacturing operations, and I’ve seen millions of dollars wasted on "next-gen" tech projects that went nowhere. You’ve seen it, too. A vendor sells you a "revolutionary" AI platform, you spend six months in pilot hell, and in the end, your operators hate it, the data is junk, and you’re left with nothing but a lighter bank account and a cynical team. The market hype is pushing us toward these massive, top-down AI projects, and frankly, it’s a recipe for failure—especially for an industrial SME.